Online Guitar Chords Followers

Free Chords and Tabs

Search lyrics, chords, tabs

Tuesday, 28 December 2010

Pickguard and Whammy Bar

Main article: Pickguard

Also known as a scratchplate. This is usually a piece of laminated plastic or other material that protects the finish of the top of the guitar from damage due to the use of a plectrum or fingernails. Electric guitars sometimes mount pickups and electronics on the pickguard. It is a common feature on steel-string acoustic guitars. Vigorous performance styles such as flamenco, which can involve the use of the guitar as a percussion instrument, call for a scratchplate to be fitted to nylon-string instruments.

Whammy Bar (Tremolo Arm)

Main article: Tremolo arm

Many electric guitars are fitted with a vibrato and pitch bend device known as a "tremolo bar (or arm)", "sissy bar", "wang bar", "slam handle", "whammy handle", and "whammy bar". The latter two terms led stompbox manufacturers to use the term 'whammy' in coming up with a pitch raising effect introduced by popular guitar effects pedal brand Digitech.

The tremolo arm is common enough that there is a technical term, hard tail, for a guitar without one.

Leo Fender, who did much to create the electric guitar, also created much confusion over the meaning of the terms "tremolo" and "vibrato" by the naming the "tremolo" unit on many of his guitars and also the "vibrato" unit on his "Vibrolux" amps. In general, vibrato is a variation in pitch, whereas tremolo is a variation in volume, so the tremolo bar is actually a vibrato bar and the "Vibrolux" amps actually had a tremolo effect. However, following Fender's example, electric guitarists traditionally reverse these meanings when speaking of hardware devices and the effects they produce. See vibrato unit for a more detailed discussion, and tremolo arm for more of the history.

Another type of the pitch bender is the B-Bender, a spring and lever device mounted in an internal cavity of a solid body electric, guitar that allows the guitarist to bend just the B string of the guitar using a lever connected to the strap handle of the guitar. The resulting pitch bend is evocative of the sound of the pedal steel guitar.

Guitar Strap

Strip of fabric with a leather or synthetic leather piece on each end. Made to hold a guitar via the shoulders, at an adjustable length to suit the position favoured by the guitarist.

Thursday, 3 June 2010

Acoustically Important Construction Features

Acoustically Important Construction Features

Three main features:- Coupling

- Material Composition

The materials from which a guitar is constructed have very direct consequences on its acoustic qualities. Because the traditional material used is wood--- often rare hardwoods and cut from as close to the centre as possible---there are certain economic and conservation issues that would be partly addressed if a more readily obtained and controllable medium were to have the required acoustic properties. Much work has been done on testing the various acoustic properties of materials that comprise the guitar. Investigations have been carried out using synthesised materials such as fibreglass, carbon fibre and various polymers, in attempts to imitate/replace existing woods. The general rationale was to produce materials with much less variation and at less cost than traditional woods, but so far the results have not been promising: - The attempts studied tended to have as much acoustic variation as traditional woods; and

- Still didn't have the stiffness-to-mass ratio, elastic moduli, damping, or longitudinal to lateral grain properties required to compete with traditional timbers.

- Plate Bracing

Unlike many other stringed instruments (such as the violin family) the guitar has a braced sound board and back plate. This is primarily due to the central position of the bridge and saddle and the large surface area of the soundboard and back, combined with their relative thinness and having no soundpost.

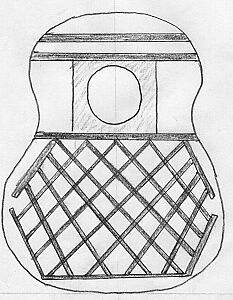

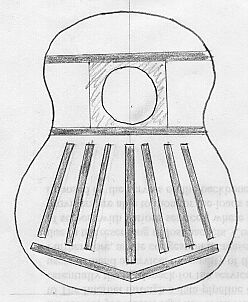

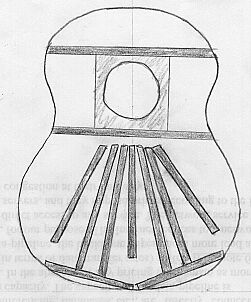

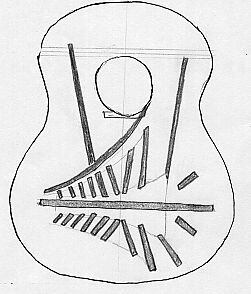

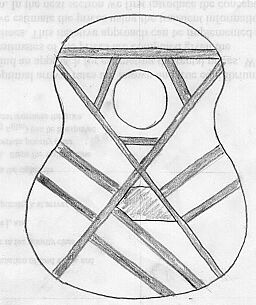

The guitar requires additional structural support. The modern, conventional, 'fan-bracing' was originally developed by the famous luthier Antonio de Torres Juan (1817-1892). A recent major development in soundboard bracing was made by Australian luthier, Greg Smallman. The structure utilises a 'criss-cross' lattice bracing composed of carbon fibre/epoxy and balsa braces, tapering in height radially outwards from underneath the bridge saddle. Dr Michael Kasha has experimented with various asymmetric bracing geometries.The bracing is acoustically critical: varying bracing techniques will alter the stiffness-to-mass ratios and elastic moduli tremendously, thereby affecting how the guitar radiates sound.

Some examples of guitar bracing geometries**

Some of the designs above may seem a little archaic or bizarre, but they were generally devised with a specific purpose. One problem encountered with guitars is that, with a symmetric bracing pattern, at a certain frequency, a node (position where vibration is a minimum) may be produced right on the point where the string that created the note is positioned, meaning that you can play the particular note on that string really quite hard, yet the sound created will have a fairly low intensity---this can often occur in the 'tripole' mode of the guitar. To counteract this effect, bracing patterns may be offset, so that the resonance modes are slightly asymmetric.

'Coupling' simply refers to an interaction between two or more vibrating elements. First of all, on a guitar, the string is excited (plucked or picked) by your fingers, vibrating the bridge, which then goes on to vibrate the soundboard and the internal air cavity, then the back and sides and so on. If these these elements interact well, the whole system is said to be strongly coupled.

The body of the guitar acts so that the high pressure vibrations at the bridge are turned into low pressure vibrations of the surrounding air. This is a form of "impedance matching", in much the same way an electrical transformer raises or lowers a potential difference and is the main principle behind speaker cone design.

The higher frequency (pitch) sounds are produced by string interaction with the bridge and then the sound board, whereas the lower frequencies are essentially driven by the internal air cavity/sound hole and ribs/back coupling effects:

The interaction looks roughly like this:

(Low Frequencies)

(High Frequencies)

Schematic of Frequency-dependent Component Oscillations. Arrows show main direction of vibratory interaction. Note that some of these influences act in both directions as mechanical feedback, eg. Bridge vibration affects the string's motion as a secondary influence.

Coupling between parts depends on geometry, sound frequency and the materials used.

Interaction strengths between various components need to be optimised according to taste; a certain amount is needed to radiate the sound transferred from the string's vibration, but too much coupling produces some harsh and very ugly tones*.

Coupling can be, and is to an extent, controlled during construction; luthiers often make use of Chladni pattern diagnosis to check the main resonance symmetries of their instrument and make any necessary changes.

Apart from being sensitively dependent on materials and bracing (see below) various other factors also influence coupling strengths, such as purfling and binding (how the sides and top/back plates are connected), bridge type and placement, right down to what sort of adhesive was used during manufacture.

Guitar construction and components

General

Guitars can be constructed to meet the demands of both left and right-handed players. Traditionally the dominant hand is assigned the task of plucking or strumming the strings. For the majority of people this entails using the right hand. This is because musical expression (dynamics, tonal expression and colour etc) is largely determined by the plucking hand, while the fretting hand is assigned the lesser mechanical task of depressing and gripping the strings. This is similar to the convention of the violin family of instruments where the right hand controls the bow. A minority, however, believe that left-handed people should learn to play guitars strung in the manner used by right-handed people, simply to standardise the instrument.

Guitars can be constructed to meet the demands of both left and right-handed players. Traditionally the dominant hand is assigned the task of plucking or strumming the strings. For the majority of people this entails using the right hand. This is because musical expression (dynamics, tonal expression and colour etc) is largely determined by the plucking hand, while the fretting hand is assigned the lesser mechanical task of depressing and gripping the strings. This is similar to the convention of the violin family of instruments where the right hand controls the bow. A minority, however, believe that left-handed people should learn to play guitars strung in the manner used by right-handed people, simply to standardise the instrument.

Headstock

The headstock is located at the end of the guitar neck furthest from the body. It is fitted with machine heads that adjust the tension of the strings, which in turn affects the pitch. Traditional tuner layout is "3+3" in which each side of the headstock has three tuners (such as on Gibson Les Pauls). In this layout, the headstocks are commonly symmetrical. Many guitars feature other layouts as well, including six-in-line (featured on Fender Stratocasters) tuners or even "4+2" (Ernie Ball Music Man). However, some guitars (such as Steinbergers) do not have headstocks at all, in which case the tuning machines are located elsewhere, either on the body or the bridge.

Nut

The nut is a small strip of bone, plastic, brass, corian, graphite, stainless steel, or other medium-hard material, at the joint where the headstock meets the fretboard. Its grooves guide the strings onto the fretboard, giving consistent lateral string placement. It is one of the endpoints of the strings' vibrating length. It must be accurately cut, or it can contribute to tuning problems due to string slippage, and/or string buzz.

Fretboard

Also called the fingerboard, the fretboard is a piece of wood embedded with metal frets that comprises the top of the neck. It is flat on classical guitars and slightly curved crosswise on acoustic and electric guitars. The curvature of the fretboard is measured by the fretboard radius, which is the radius of a hypothetical circle of which the fretboard's surface constitutes a segment. The smaller the fretboard radius, the more noticeably curved the fretboard is. Most modern guitars feature a 12" neck radius, while older guitars from the 1960s and 1970s usually feature a 6-8" neck radius. Pinching a string against the fretboard effectively shortens the vibrating length of the string, producing a higher pitch. Fretboards are most commonly made of rosewood, ebony, maple, and sometimes manufactured or composite materials such as HPL or resin. See below on section "Neck" for the importance of the length of the fretboard in connection to other dimensions of the guitar.

Frets

Frets are metal strips (usually nickel alloy or stainless steel) embedded along the fretboard and located at exact points that divide the scale length in accordance with a specific mathematical formula. Pressing a string against a fret determines the strings' vibrating length and therefore its resultant pitch. The pitch of each consecutive fret is defined at a half-step interval on the chromatic scale. Standard classical guitars have 19 frets and electric guitars between 21 to 24 frets (though Ibanez has issued guitars with as many as 36 frets.)

Frets are laid out to a mathematical ratio that results in equal tempered division of the octave. The ratio of the spacing of two consecutive frets is the twelfth root of two. The twelfth fret divides the scale length in two exact halves and the 24th fret position divides the scale length in half yet again. Every twelve frets represents one octave. In practice, luthiers determine fret positions using the constant 17.817, which is derived from the twelfth root of two (21/12). The scale length divided by this value yields the distance from the nut to the first fret. That distance is subtracted from the scale length and the result is divided in two sections by the constant to yield the distance from the first fret to the second fret. Positions for the remainder of the frets are calculated in like manner. Actual fret spacing does not use this exact value; the fret spacing on the fretboard was also done by trial and error (testing) method over the ages.

There are several different fret gauges, which can be fitted according to player preference. Among these are "jumbo" frets, which have much thicker gauge, allowing for use of a slight vibrato technique from pushing the string down harder and softer. "Scalloped" fretboards, where the wood of the fretboard itself is "scooped out" between the frets allows a dramatic vibrato effect. Fine frets, much flatter, allow a very low string-action but require other conditions such as curvature of the neck to be well maintained in order to prevent buzz.

On steel-string guitars, frets are eventually bound to wear down; when this happens, frets can be replaced or, to a certain extent, leveled, polished, recrowned, or reshaped as required.

Truss rod

The truss rod is a metal rod that runs along the inside of the neck. It is used to correct changes to the neck's curvature caused by the neck timbers aging, changes in humidity or to compensate for changes in the tension of strings. The tension of the rod and neck assembly is adjusted by a hex nut or an allen-key bolt on the rod, usually located either at the headstock, sometimes under a cover, or just inside the body of the guitar underneath the fretboard and accessible through the sound hole. Some truss rods can only be accessed by removing the neck. The truss rod counteracts the immense amount of tension the strings place on the neck, bringing the neck back to a straighter position. Turning the truss rod clockwise will tighten it, counteracting the tension of the strings and straightening the neck or creating a backward bow. Turning the truss rod counter-clockwise will loosen it, allowing string tension to act on the neck and creating a forward bow. Adjusting the truss rod affects the intonation of a guitar as well as the height of the strings from the fingerboard, called the action. Some truss rod systems, called "double action" truss systems, tighten both ways, allowing the neck to be pushed both forward and backward (standard truss rods can only be released to a point beyond which the neck will no longer be compressed and pulled backward).

Classical guitars do not require truss rods as their nylon strings exert a lower tensile force with lesser potential to cause structural problems. However their necks are often reinforced with a strip of harder wood, such as an ebony strip running down the back of a cedar neck. There is no tension adjustment on this form of reinforcement.

Inlays

Inlays are visual elements set into the exterior surface of a guitar. The typical locations for inlay are on the fretboard, headstock, and on acoustic guitars around the soundhole, known as the rosette. Inlays range from simple plastic dots on the fretboard to intricate works of art covering the entire exterior surface of a guitar (front and back). Some guitar players have used LEDs in the fretboard to produce a unique lighting effects onstage.

Fretboard inlays are most commonly shaped like dots, diamond shapes, parallelograms, or large blocks in between the frets. Dots are usually inlaid into the upper edge of the fretboard in the same positions, small enough to be visible only to the player. These usually appear on the odd numbered frets, but also on the 12th fret (the one octave mark) instead of the 11th and 13th frets. Some older or high-end instruments have inlays made of mother of pearl, abalone, ivory, coloured wood or other exotic materials and designs. Simpler inlays are often made of plastic or painted. High-end classical guitars seldom have fretboard inlays as a well trained player is expected to know his or her way around the instrument.

In addition to fretboard inlay, the headstock and soundhole surround are also frequently inlaid. The manufacturer's logo or a small design is often inlaid into the headstock. Rosette designs vary from simple concentric circles to delicate fretwork mimicking the historic rosette of lutes. Bindings that edge the finger and sound boards are sometimes inlaid. Some instruments have a filler strip running down the length and behind the neck, used for strength and/or to fill the cavity through which the trussrod was installed in the neck.

Elaborate inlays are a decorative feature of many limited edition, high-end and custom-made guitars. Guitar manufacturers often release such guitars to celebrate significant or historic milestones.

Neck

A guitar's frets, fretboard, tuners, headstock, and truss rod, all attached to a long wooden extension, collectively constitute its neck. The wood used to make the fretboard will usually differ from the wood in the rest of the neck. The bending stress on the neck is considerable, particularly when heavier gauge strings are used (see Tuning), and the ability of the neck to resist bending (see Truss rod) is important to the guitar's ability to hold a constant pitch during tuning or when strings are fretted. The rigidity of the neck with respect to the body of the guitar is one determinant of a good instrument versus a poor one. The shape of the neck can also vary, from a gentle "C" curve to a more pronounced "V" curve. There are many different types of neck profiles available, giving the guitarist many options. Some aspects to consider in a guitar neck may be the overall width of the fingerboard, scale (distance between the frets), the neck wood, the type of neck construction (for example, the neck may be glued in or bolted on), and the shape (profile) of the back of the neck. Other type of material used to make guitar necks are graphite (Steinberger guitars), aluminium (Kramer Guitars, Travis Bean and Veleno guitars), or carbon fiber (Modulus Guitars and ThreeGuitars).

Double neck electric guitars have two necks, allowing the musician to quickly switch between guitar sounds.

Neck joint or 'Heel'

This is the point at which the neck is either bolted or glued to the body of the guitar. Almost all acoustic guitars, with the primary exception of Taylors, have glued (otherwise known as set) necks, while electric guitars are constructed using both types.

Commonly used set neck joints include mortise and tenon joints (such as those used by CF Martin & Co. guitars), dovetail joints (also used by CF Martin on the D28 and similar models) and Spanish heel neck joints which are named after the shoe they resemble and commonly found in classical guitars. All three types offer stability. Bolt-on necks, though they are historically associated with cheaper instruments, do offer greater flexibility in the guitar's set-up, and allow easier access for neck joint maintenance and repairs.

Another type of neck, only available for solid body electric guitars, is the neck-through-body construction. These are designed so that everything from the machine heads down to the bridge are located on the same piece of wood. The sides (also known as wings) of the guitar are then glued to this central piece. Some luthiers prefer this method of construction as they claim it allows better sustain of each note. Some instruments may not have a neck joint at all, having the neck and sides built as one piece and the body built around it.

Strings

Modern guitar strings are constructed of metal, polymers, or animal or plant product materials.

Instruments utilising "steel" strings may have strings made of alloys incorporating steel, nickel or phosphor bronze. Classical and flamenco instruments historically used gut strings, but these have been superseded by polymer materials, such as nylon and fluorocarbon materials. Bass strings for both instruments are wound rather than monofilament.

Body (acoustic guitar)

In acoustic guitars, string vibration is transmitted through the bridge and saddle to the body via sound board. The sound board is typically made of tone woods such as spruce or cedar. Timbers for tone woods are chosen for both strength and ability to transfer mechanical energy from the strings to the air within the guitar body. Sound is further shaped by the characteristics of the guitar body's resonant cavity.

In electric guitars, transducers known as pickups convert string vibration to an electric signal, which in turn is amplified and fed to speakers, which vibrate the air to produce the sounds we hear. Nevertheless, the body of the electric guitar still performs a role in shaping the resultant tonal signature.

In an acoustic instrument, the body of the guitar is a major determinant of the overall sound quality. The guitar top, or soundboard, is a finely crafted and engineered element made of tonewoods such as spruce and red cedar. This thin piece of wood, often only 2 or 3 mm thick, is strengthened by differing types of internal bracing. The top is considered by many luthiers to be the dominant factor in determining the sound quality. The majority of the instrument's sound is heard through the vibration of the guitar top as the energy of the vibrating strings is transferred to it.

Body size, shape and style has changed over time. 19th century guitars, now known as salon guitars, were smaller than modern instruments. Differing patterns of internal bracing have been used over time by luthiers. Torres, Hauser, Ramirez, Fleta, and C.F. Martin were among the most influential designers of their time. Bracing not only strengthens the top against potential collapse due to the stress exerted by the tensioned strings, but also affects the resonance characteristics of the top. The back and sides are made out of a variety of timbers such as mahogany, Indian rosewood and highly regarded Brazilian rosewood (Dalbergia nigra). Each one is primarily chosen for their aesthetic effect and can be decorated with inlays and purfling.

The body of an acoustic guitar has a sound hole through which sound is projected. The sound hole is usually a round hole in the top of the guitar under the strings. Air inside the body vibrates as the guitar top and body is vibrated by the strings, and the response of the air cavity at different frequencies is characterised, like the rest of the guitar body, by a number of resonance modes at which it responds more strongly.

Instruments with larger areas for the guitar top were introduced by Martin in an attempt to create louder volume levels. The popularity of the larger "dreadnought" body size amongst acoustic performers is related to the greater sound volume produced.

Body (electric guitar)

Most electric guitar bodies are made of wood and include a plastic pick guard. Boards wide enough to use as a solid body are very expensive due to the worldwide depletion of hardwood stock since the 70's, so the wood is rarely one solid piece. Most bodies are made of two pieces of wood with some of them including a seam running down the centre line of the body. The most common woods used for electric guitar body construction include maple, basswood, ash, poplar, alder, and mahogany. Many bodies will consist of good sounding but inexpensive woods, like ash, with a "top", or thin layer of another, more attractive wood (such as maple with a natural "flame" pattern) glued to the top of the basic wood. Guitars constructed like this are often called "flame tops". The body is usually carved or routed to accept the other elements, such as the bridge, pickup, neck, and other electronic components. Most electrics have a polyurethane or nitrocellulose lacquer finish. Other alternative materials to wood, are used in guitar body construction. Some of these include carbon composites, plastic material (such as polycarbonate) and aluminium alloys.

Pickups

Pickups are transducers attached to a guitar that detect (or "pick up") string vibrations and convert the mechanical energy of the string into electrical energy. The resultant electrical signal can then be electronically amplified. The most common type of pickup is electromagnetic in design. These contain magnets that are tightly wrapped in a coil, or coils, of copper wire. Such pickups are usually placed right underneath the guitar strings. Electromagnetic pickups work on the same principles and in a similar manner to an electrical generator. The vibration of the strings causes a small voltage to be created in the coils surrounding the magnets; this signal voltage is later amplified.

Traditional electromagnetic pickups are either single-coil or double-coil. Single-coil pickups are susceptible to noise induced from electric fields, usually mains-frequency (60 or 50 hertz) hum. The introduction of the double-coil humbucker in the mid-1950s did away with this problem through the use of two coils, one of which is wired in a reverse polarity orientation.

The types and models of pickups used can greatly affect the tone of the guitar. Typically, humbuckers, which are two magnet–coil assemblies attached to each other are traditionally associated with a heavier sound. Single-coil pickups, one magnet wrapped in copper wire, are used by guitarists seeking a brighter, twangier sound with greater dynamic range.

Modern pickups are tailored to the sound desired. A commonly applied approximation used in selection of a pickup is that less wire (lower DC resistance) = brighter sound, more wire = "fat" tone. Other options include specialized switching that produces coil-splitting, in/out of phase and other effects. Guitar circuits are either active, needing a battery to power their circuit, or, as in most cases, equipped with a passive circuit.

Fender Stratocaster type guitars generally utilize three single-coil pickups, while most Gibson Les Paul types use humbucker pickups.

Piezoelectric, or piezo, pickups represent another class of pickup. These employ piezoelectricity to generate the musical signal and are popular in hybrid electro-acoustic guitars. A crystal is located under each string, usually in the saddle. When the string vibrates, the shape of the crystal is distorted, and the stresses associated with this change produce tiny voltages across the crystal that can be amplified and manipulated.

Some piezo-equipped guitars use what is known as a hexaphonic pickup. "Hex" is a prefix meaning six. In a hexaphonic pickup separate outputs are obtained from discrete piezoelectric pickups for each of the six strings. This arrangement allows the signal to be easily modified by on-board modelling electronics, as in the Line 6 Variax brand of electric guitars; the guitars allow for a variety of different sounds to be obtained by digitally manipulating the signal. This allows a guitar to mimic many vintage models of guitar, as well as output alternate tunings without the need to adjust the strings.

Another use for hexaphonic pickups is to send the output signals to a MIDI interpretation device, which determines the note pitch, duration, attack and decay characteristics and so forth. The MIDI (Musical Instrument Digital Interface) interpreter then sends the note information to a sound bank device. The resulting sound can closely mimic numerous types of instruments.

Electronics

On guitars that have them, these components and the wires that connect them allow the player to control some aspects of the sound like volume or tone. These at their simplest consist of passive components such as potentiometers and capacitors, but may also include specialized integrated circuits or other active components requiring batteries for power, for preamplification and signal processing, or even for assistance in tuning. In many cases the electronics have some sort of shielding to prevent pickup of external interference and noise.

Lining, Binding, and Purfling

The top, back and ribs of an acoustic guitar body are very thin (1-2 mm), so a flexible piece of wood called lining is glued into the corners where the rib meets the top and back. This interior reinforcement provides 5 to 20 mm of solid gluing area for these corner joints. Solid linings are often used in classical guitars, while kerfed lining is most often found in steel string acoustics. Kerfed lining is also called kerfing (because it is scored, or kerfed to allow it to bend with the shape of the rib).

During final construction, a small section of the outside corners is carved or routed out and then filled with binding material on the outside corners and decorative strips of material next to the binding, which are called purfling. This binding serves to seal off the endgrain of the top and back. Purfling can also appear on the back of an acoustic guitar, marking the edge joints of the two or three sections of the back.

Binding and purfling materials are generally made of either wood or plastic.

Bridge

The main purpose of the bridge on an acoustic guitar is to transfer the vibration from the strings to the soundboard, which vibrates the air inside of the guitar, thereby amplifying the sound produced by the strings.

On both electric and acoustic guitars, the bridge holds the strings in place on the body. There are many varied bridge designs. There may be some mechanism for raising or lowering the bridge to adjust the distance between the strings and the fretboard (action), and/or fine-tuning the intonation of the instrument. Some are spring-loaded and feature a "whammy bar", a removable arm which allows the player to modulate the pitch moving the bridge up and down. The whammy bar is sometimes also referred to as a "tremolo bar" (see Tremolo for further discussion of this term – the effect of rapidly changing pitch produced by a whammy bar is more correctly called "vibrato"). Some bridges also allow for alternate tunings at the touch of a button.

On almost all modern electric guitars, the bridge is adjustable for each string so that intonation stays correct up and down the neck. If the open string is in tune but sharp or flat when frets are pressed, the bridge can be adjusted with a screwdriver or hex key to remedy the problem. In general, flat notes are corrected by moving the bridge forward and sharp notes by moving it backwards. On an instrument correctly adjusted for intonation, the actual length of each string from the nut to the bridge saddle will be slightly but measurably longer than the scale length of the instrument. This additional length is called compensation, which flattens all notes a bit to compensate for the sharping of all fretted notes caused by stretching the string during fretting.

Pickguard

Also known as a scratchplate. This is usually a piece of laminated plastic or other material that protects the finish of the top of the guitar from damage due to the use of a plectrum or fingernails. Electric guitars sometimes mount pickups and electronics on the pickguard. It is a common feature on steel-string acoustic guitars. Vigorous performance styles such as flamenco, which can involve the use of the guitar as a percussion instrument, call for a scratchplate to be fitted to nylon-string instruments.

Tremolo arm

Many electric guitars are fitted with a vibrato and pitch bend device known as a "tremolo bar (or arm)", "sissy bar", "wang bar", "slam handle", "whammy handle", and "whammy bar". The latter two terms led stompbox manufacturers to use the term 'whammy' in coming up with a pitch raising effect introduced by popular guitar effects pedal brand "Digitech".

The tremolo arm is common enough that there is a technical term, hard tail, for a guitar without one.

Leo Fender, who did much to create the electric guitar, also created much confusion over the meaning of the terms "tremolo" and "vibrato" by the naming the "tremolo" unit on many of his guitars and also the "vibrato" unit on his "Vibrolux" amps. In general, vibrato is a variation in pitch, whereas tremolo is a variation in volume, so the tremolo bar is actually a vibrato bar and the "Vibrolux" amps actually had a tremolo effect. However, following Fender's example, electric guitarists traditionally reverse these meanings when speaking of hardware devices and the effects they produce. See vibrato unit for a more detailed discussion, and tremolo arm for more of the history.

Another type of pitch bender is the B-Bender, a spring and lever device mounted in an internal cavity of a solid body electric, guitar that allows the guitarist to bend just the B string of the guitar using a lever connected to the strap handle of the guitar. The resulting pitch bend is evocative of the sound of the pedal steel guitar.

Guitar Strap

Strip of fabric with a leather or synthetic leather piece on each end. Made to hold a guitar via the shoulders, at an adjustable length to suit the position favoured by the guitarist.

Self-tuning guitars

Self-tuning guitars are computerized guitars programmed to tune themselves. The Gibson Robot guitar, released in 2007, is often mistaken as the first of this kind, but was preceded by the Transperformance system by at least 20 years. Gibson is currently working on a new self-tuning model called the Dark Fire.

The guitar is one technology that was designed to have a positive impact on society. It was meant to produce appealing sounds and bring joy to people. On the flip side it has contributed to capitalism through encouraging competition through records sales and concerts. Not to say that is a bad thing, but it does happen. It has changed the way people incorporate music into there lives. Maybe it was the record companies that really encouraged capitalism. They were definitely encouraged by this instrument in the age of Rock and Roll.

It has had an impact on be personally for the past few months. The tenant living upstairs from me plays and screeches day and night. He has immediate satisfaction from playing, which I think was probably one of the ideas behind the invention, I believe his roommates do too. Why else would they put up with it? He does not realize the effects is has on others in the area. Many nights I do not get a good nights rest because of this. The sound travels clearly into my bedroom. This causes me to be tired and crabby the next day, potentially affecting others I interact with. I also do not do my work as effectively as I may have if well rested. What if I had the potential to do something for the world and did not achieve it because I missed an opportunity to learn something pivotal this semester. The world could suffer because I didn’t learn because I was exhausted from the guy upstairs pounding out tunes on an instrument design to bring pleasure to the world. Or maybe I should just go have a talk with him.

Guitar accessories

Guitar accessories

Though a guitar may be played on its own, there are a variety of common accessories used for holding and playing the guitar.

Main article: Capo

A capo (short for capotasto) is used to change the pitch of open strings. Capos are clipped onto the fret board with the aid of spring tension, or in some models, elastic tension. To raise the guitar's pitch by one semitone, the player would clip the capo onto the fret board just below the first fret. Its use allows players to play in different keys without having to change the chord formations they use. Because of the ease with which they allow guitar players to change keys, they are sometimes referred to as "cheaters" or the "hillbilly crutch." Classical performers are known to use them to enable modern instruments to match the pitch of historical instruments such as the renaissance lute.

Slides

Main article: Slide Guitar

A slide, (neck of a bottle, knife blade or round metal bar) used in blues and rock to create a glissando or 'Hawaiian' effect. The necks of bottles were often used in blues and country music. Modern slides are constructed of glass, plastic, ceramic, chrome, brass or steel, depending on the weight and tone desired. An instrument that is played exclusively in this manner, (using a metal bar) is called a steel guitar or pedal steel. Slide playing to this day is very popular in blues music and country music. Some slide players use a so called Dobro guitar.

Some performers that have become famous for playing slide are Robert Johnson, Elmore James, Ry Cooder, George Harrison, Bonnie Raitt, Derek Trucks, Warren Haynes, Duane Allman, Muddy Waters, Rory Gallagher, and George Thorogood.

Pickguard, Whammy Bar, Guitar Strap

Main article: Pickguard

Also known as a scratchplate. This is usually a piece of laminated plastic or other material that protects the finish of the top of the guitar from damage due to the use of a plectrum or fingernails. Electric guitars sometimes mount pickups and electronics on the pickguard. It is a common feature on steel-string acoustic guitars. Vigorous performance styles such as flamenco, which can involve the use of the guitar as a percussion instrument, call for a scratchplate to be fitted to nylon-string instruments.

Whammy Bar (Tremolo Arm)

Main article: Tremolo arm

Many electric guitars are fitted with a vibrato and pitch bend device known as a "tremolo bar (or arm)", "sissy bar", "wang bar", "slam handle", "whammy handle", and "whammy bar". The latter two terms led stompbox manufacturers to use the term 'whammy' in coming up with a pitch raising effect introduced by popular guitar effects pedal brand Digitech.

The tremolo arm is common enough that there is a technical term, hard tail, for a guitar without one.

Leo Fender, who did much to create the electric guitar, also created much confusion over the meaning of the terms "tremolo" and "vibrato" by the naming the "tremolo" unit on many of his guitars and also the "vibrato" unit on his "Vibrolux" amps. In general, vibrato is a variation in pitch, whereas tremolo is a variation in volume, so the tremolo bar is actually a vibrato bar and the "Vibrolux" amps actually had a tremolo effect. However, following Fender's example, electric guitarists traditionally reverse these meanings when speaking of hardware devices and the effects they produce. See vibrato unit for a more detailed discussion, and tremolo arm for more of the history.

Another type of pitch bender is the B-Bender, a spring and lever device mounted in an internal cavity of a solid body electric, guitar that allows the guitarist to bend just the B string of the guitar using a lever connected to the strap handle of the guitar. The resulting pitch bend is evocative of the sound of the pedal steel guitar.

Guitar Strap

Strip of fabric with a leather or synthetic leather piece on each end. Made to hold a guitar via the shoulders, at an adjustable length to suit the position favoured by the guitarist.

On guitars that have them, these components and the wires that connect them allow the player to control some aspects of the sound like volume or tone. These at their simplest consist of passive components such as potentiometers and capacitors, but may also include specialized integrated circuits or other active components requiring batteries for power, for preamplification and signal processing, or even for assistance in tuning. In many cases the electronics have some sort of shielding to prevent pickup of external interference and noise.

[edit] Lining, Binding, and Purfling

The top, back and ribs of an acoustic guitar body are very thin (1-2 mm), so a flexible piece of wood called lining is glued into the corners where the rib meets the top and back. This interior reinforcement provides 5 to 20 mm of solid gluing area for these corner joints. Solid linings are often used in classical guitars, while kerfed lining is most often found in steel string acoustics. Kerfed lining is also called kerfing (because it is scored, or kerfed to allow it to bend with the shape of the rib).

During final construction, a small section of the outside corners is carved or routed out and then filled with binding material on the outside corners and decorative strips of material next to the binding, which are called purfling. This binding serves to seal off the endgrain of the top and back. Purfling can also appear on the back of an acoustic guitar, marking the edge joints of the two or three sections of the back.

Binding and purfling materials are generally made of either wood or plastic.

Pickups

Main article: Pick up (music technology)

Pickups - Pickups are transducers attached to a guitar that detect (or "pick up") string vibrations and convert the mechanical energy of the string into electrical energy. The resultant electrical signal can then be electronically amplified. The most common type of pickup is electromagnetic in design. These contain magnets that are tightly wrapped in a coil, or coils, of copper wire. Such pickups are usually placed right underneath the guitar strings. Electromagnetic pickups work on the same principles and in a similar manner to an electrical generator. The vibration of the strings causes a small voltage to be created in the coils surrounding the magnets, this signal voltage is later amplified.

Traditional electromagnetic pickups are either single-coil or double-coil. Single-coil pickups are susceptible to noise induced from electric fields, usually mains-frequency (60 or 50 hertz) hum. The introduction of the double-coil humbucker in the mid-1950s did away with this problem through the use of two coils, one of which is wired in a reverse polarity orientation.

The types and models of pickups used can greatly affect the tone of the guitar. Typically, humbuckers, which are two magnet–coil assemblies attached to each other are traditionally associated with a heavier sound. Single-coil pickups, one magnet wrapped in copper wire, are used by guitarists seeking a brighter, twangier sound with greater dynamic range.

Piezoelectric, or piezo, pickups represent another class of pickup. These employ piezoelectricity to generate the musical signal and are popular in hybrid electro-acoustic guitars. A crystal is located under each string, usually in the saddle. When the string vibrates, the shape of the crystal is distorted, and the stresses associated with this change produce tiny voltages across the crystal that can be amplified and manipulated.

Some piezo-equipped guitars use what is known as a hexaphonic pickup. "Hex" is a prefix meaning six. In a hexaphonic pickup separate outputs are obtained from discrete piezoelectric pickups for each of the six strings. This arrangement allows the signal to be easily modified by on-board modelling electronics, as in the Line 6 Variax brand of electric guitars; the guitars allow for a variety of different sounds to be obtained by digitally manipulating the signal. This allows a guitar to mimic many vintage models of guitar, as well as output alternate tunings without the need to adjust the strings.

Another use for hexaphonic pickups is to send the output signals to a MIDI interpretation device, which determines the note pitch, duration, attack and decay characteristics and so forth. The MIDI (Musical Instrument Digital Interface) interpreter then sends the note information to a sound bank device. The resulting sound can closely mimic numerous types of instruments.

Body of electric guitar

See also: Solid body

Most electric guitar bodies are made of wood and include a plastic pick guard. Boards wide enough to use as a solid body are very expensive due to the worldwide depletion of hardwood stock since the 70's, so the wood is rarely one solid piece. Most bodies are made of two pieces of wood with some of them including a seam running down the centre line of the body. The most common woods used for electric guitar body construction include maple, basswood, ash, poplar, alder, and mahogany. Many bodies will consist of good sounding but inexpensive woods, like ash, with a "top", or thin layer of another, more attractive wood (such as maple with a natural "flame" pattern) glued to the top of the basic wood. Guitars constructed like this are often called "flame tops". The body is usually carved or routed to accept the other elements, such as the bridge, pickup, neck, and other electronic components. Most electrics have a polyurethane or nitrocellulose lacquer finish. Other alternative materials to wood, are used in guitar body construction. Some of these include carbon composites, plastic material (such as polycarbonate) and aluminium alloys.

Neck joint or 'Heel'

See also: Set-in neck, Bolt-on neck, and Neck-through

This is the point at which the neck is either bolted or glued to the body of the guitar. Almost all acoustic steel-string guitars, with the primary exception of Taylors, have glued (otherwise known as set) necks, while electric guitars are constructed using both types. Most classical guitars have a neck and headblock carved from one piece of wood, known as a "Spanish heel."

Commonly used set neck joints include mortise and tenon joints (such as those used by CF Martin & Co. guitars), dovetail joints (also used by CF Martin on the D28 and similar models) and Spanish heel neck joints which are named after the shoe they resemble and commonly found in classical guitars. All three types offer stability. Bolt-on necks, though they are historically associated with cheaper instruments, do offer greater flexibility in the guitar's set-up, and allow easier access for neck joint maintenance and repairs.

Another type of neck, only available for solid body electric guitars, is the neck-through-body construction. These are designed so that everything from the machine heads down to the bridge are located on the same piece of wood. The sides (also known as wings) of the guitar are then glued to this central piece. Some luthiers prefer this method of construction as they claim it allows better sustain of each note. Some instruments may not have a neck joint at all, having the neck and sides built as one piece and the body built around it.

Guitar Neck

picture of guitar neck

Main article: Neck (music)

A guitar's frets, fretboard, tuners, headstock, and truss rod, all attached to a long wooden extension, collectively constitute its neck. The wood used to make the fretboard will usually differ from the wood in the rest of the neck. The bending stress on the neck is considerable, particularly when heavier gauge strings are used (see Tuning), and the ability of the neck to resist bending (see Truss rod) is important to the guitar's ability to hold a constant pitch during tuning or when strings are fretted. The rigidity of the neck with respect to the body of the guitar is one determinant of a good instrument versus a poor one. The shape of the neck can also vary, from a gentle "C" curve to a more pronounced "V" curve. There are many different types of neck profiles available, giving the guitarist many options. Some aspects to consider in a guitar neck may be the overall width of the fingerboard, scale (distance between the frets), the neck wood, the type of neck construction (for example, the neck may be glued in or bolted on), and the shape (profile) of the back of the neck. Other type of material used to make guitar necks are graphite (Steinberger guitars), aluminium (Kramer Guitars, Travis Bean and Veleno guitars), or carbon fiber (Modulus Guitars and ThreeGuitars).

Double neck electric guitars have two necks, allowing the musician to quickly switch between guitar sounds.

Free chords

lyrics, chords, tabs labels

- Guitar Lessons and Tutorials (67)

- bangla guitar chords (21)

- chords and tabs of song (142)

- english guitar chords (27)

- hindi guitar chords (26)

- history of guitar (7)